Get Peace of Mind and Improve Reliability

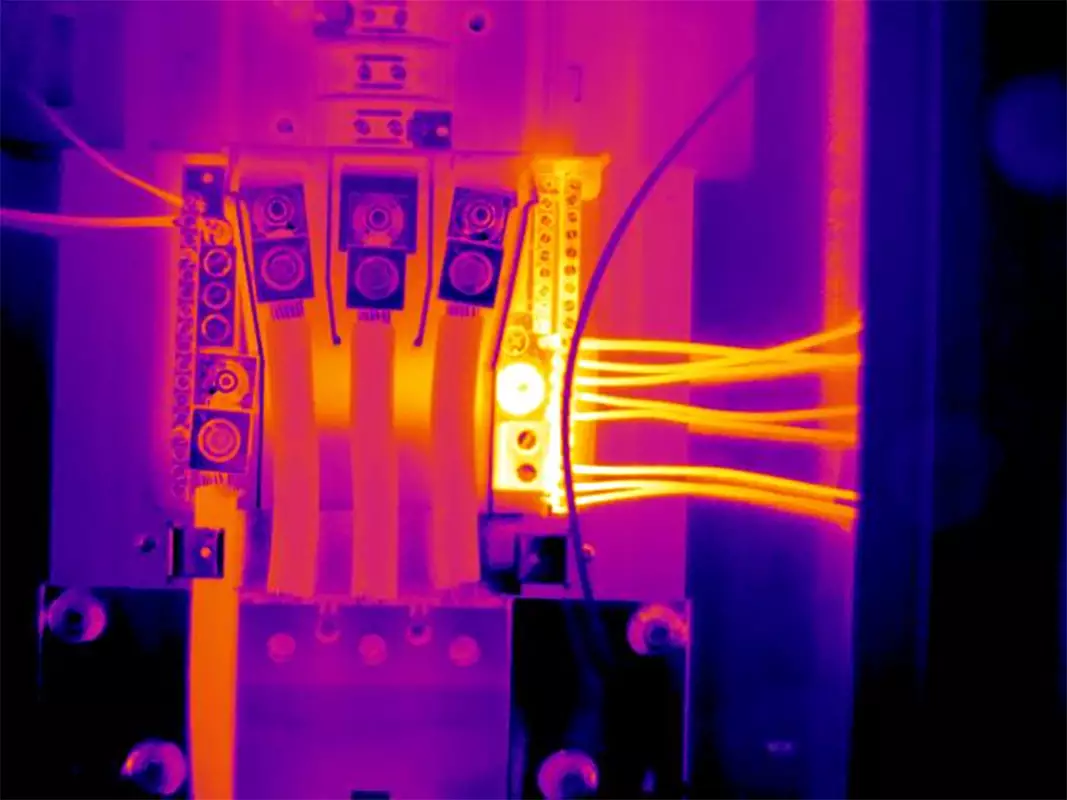

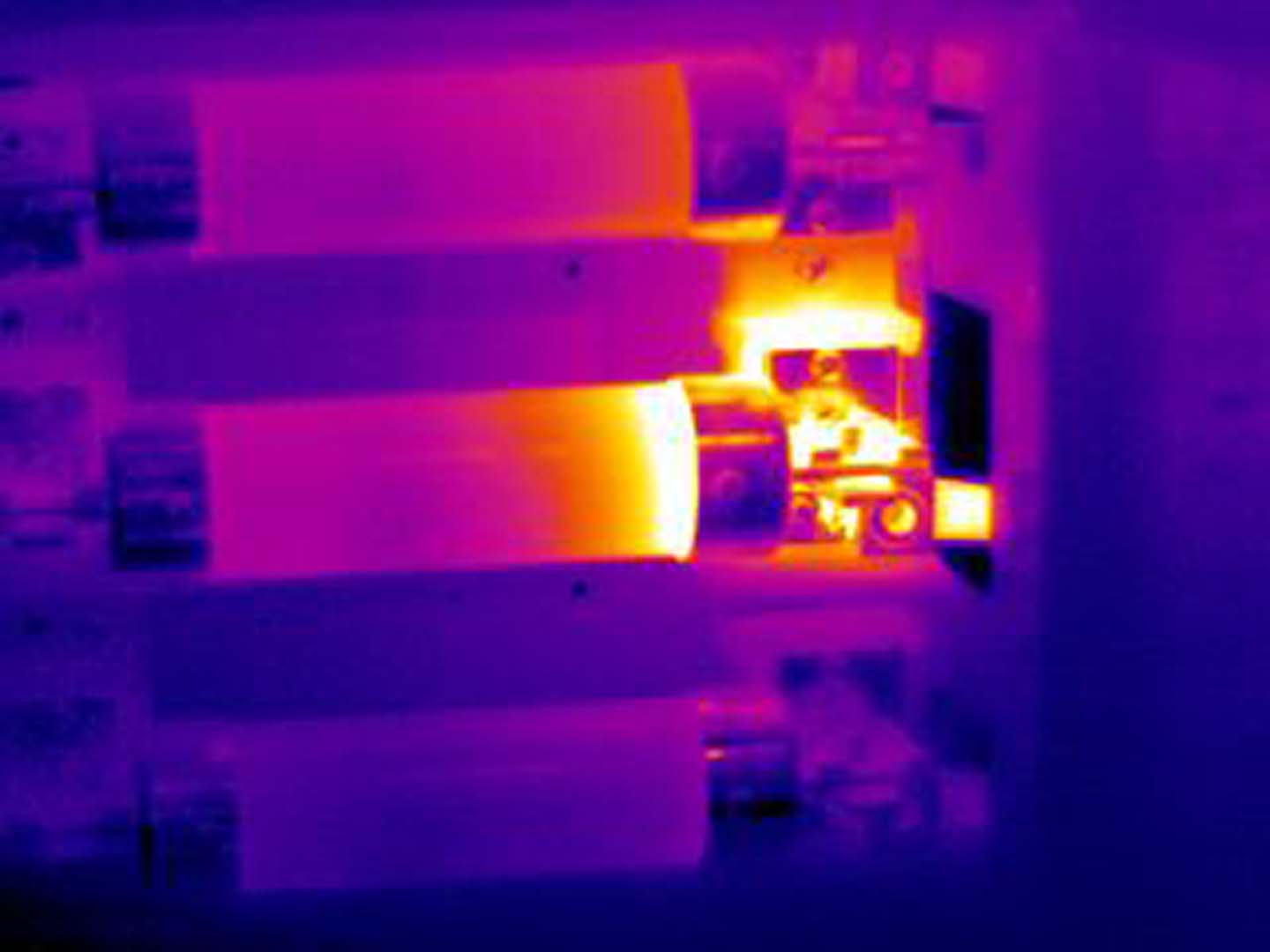

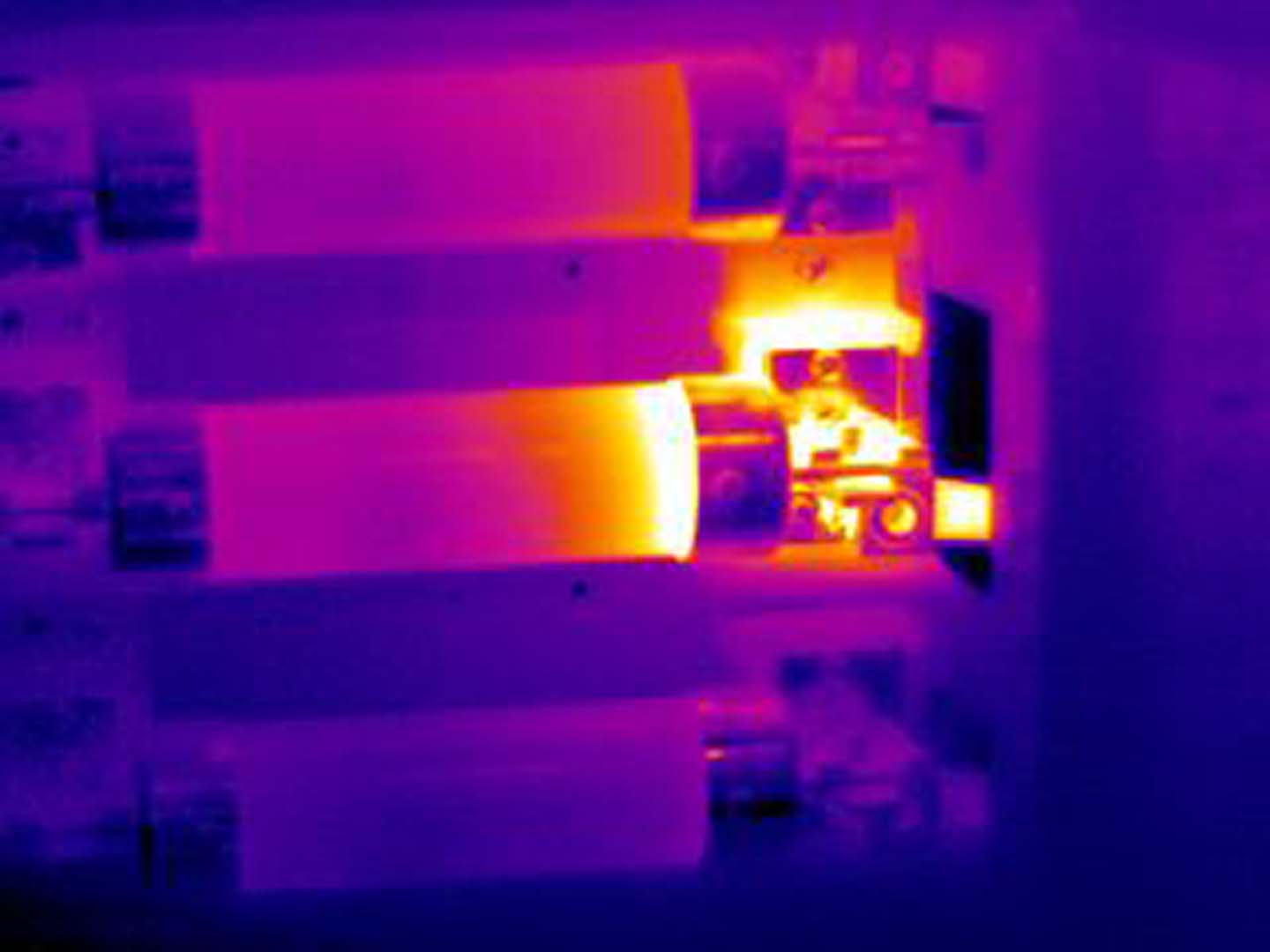

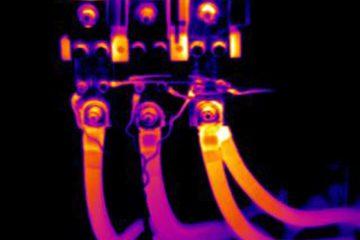

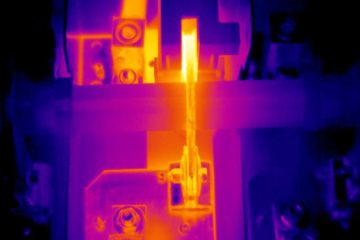

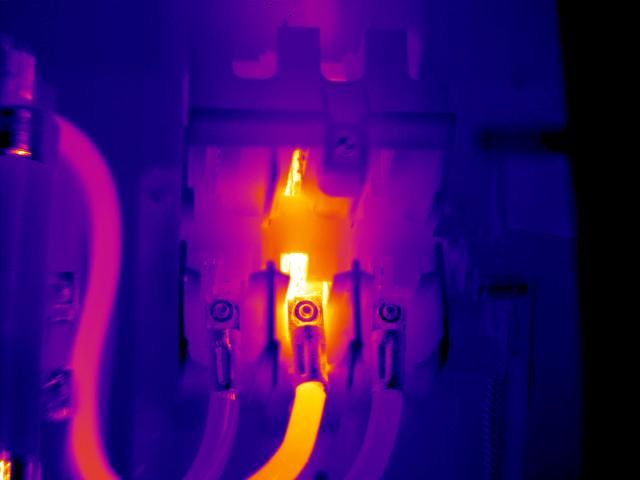

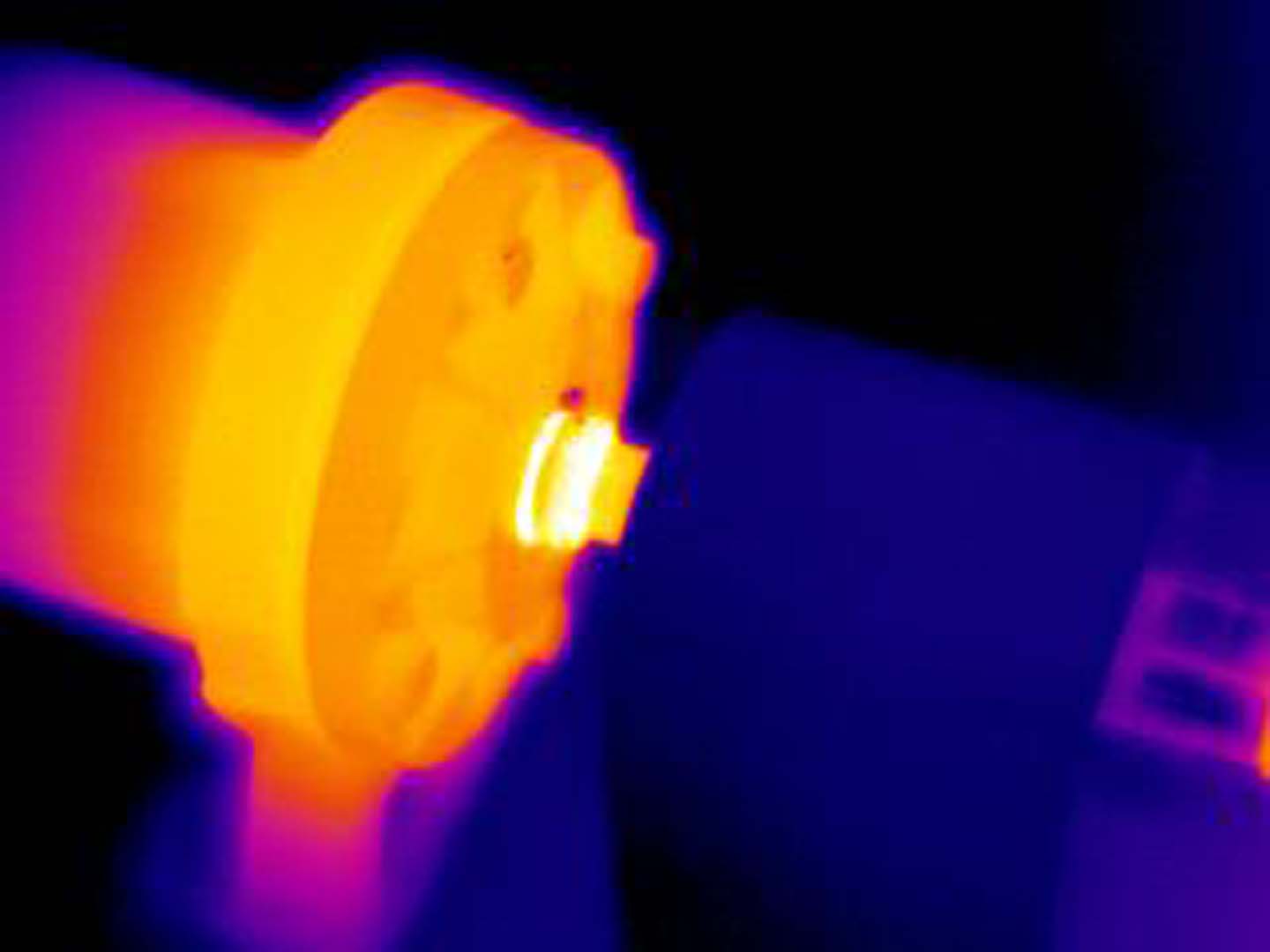

Infrared inspections improve reliability by locating thermal anomalies that can shut your facility down. Through a thorough and systematic process, IR inspections discover imminent breakdown points in your facility allowing maintenance and repair prior to failure. These inspections frequently find loose or dirty connections, phase imbalances, overloaded breakers and many potential systems problems.

Commonly Inspected Items:

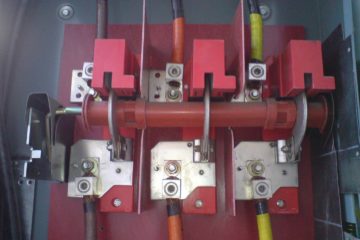

- Switchgear

- Motor Control Centers

- Transformers

- Breaker Panels

- Service Disconnects

- Starters

- Automatic Transfer Switches

- Bus Runs

- Chillers and Roof Top HVAC Equipment

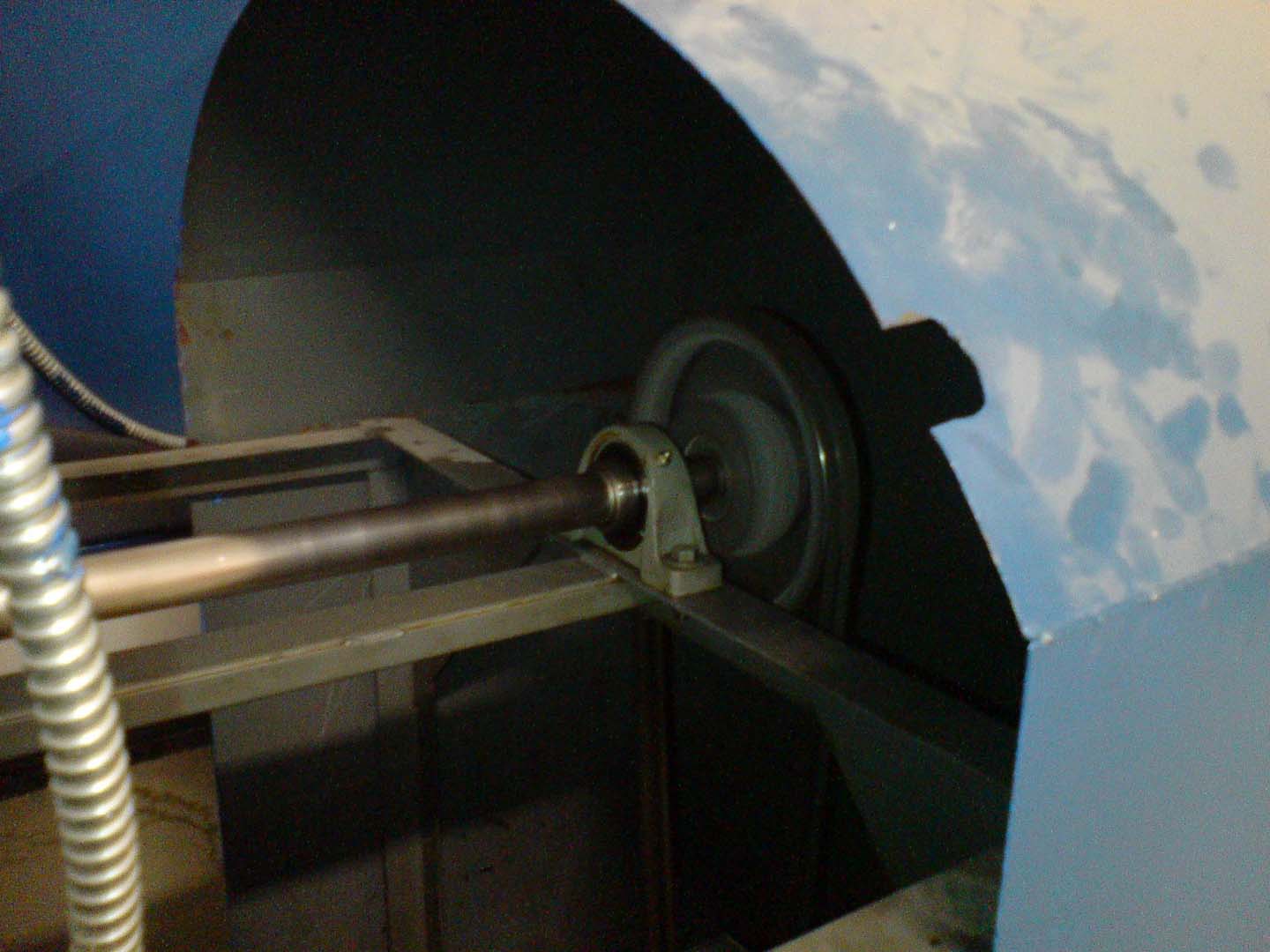

- Motors/Pumps/Bearings

- VFD’s

- Lighting/Heating Contactors

Save Money While Ensuring Safety of Your Facilities

Annual Infrared Inspections Save Thousands!

- Infrared surveys typically save $9,651 with an average of 8 problems per survey

- Savings for intermediate/minor problems is $500

- Cost savings for critical/serious problems is $3,000

- Electrical fire damage costs an average of $750,000

* CNA Insurance, Infrared Thermography – Revealing the Hidden Risks, 2017

Inspections Done Right!

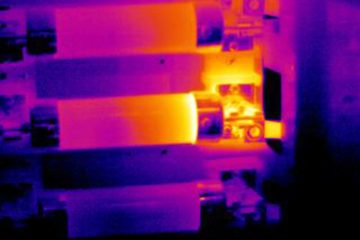

Trained by our Master Thermographer with more than 30 years of experience, our Certified Thermographers conduct infrared non-destructive testing. NDT pinpoints problems that cannot be seen with the naked eye. Our exclusive reporting system categorizes anomalies into four tiers of severity, allowing your team to prioritize repairs easily. Every report includes our timesaving, easy-to-read equipment list empowering anyone to quickly locate problems identified.

Thermography at Work

Safety Procedures:

- HOT/SHOT meets or exceeds NFPA 70E and OSHA requirements

- Trained technicians can safely remove and replace panel covers

- Level II or higher Infrared Thermographers